+86 186 3170 8948

+86 186 3170 8948

Knowledge

Jan. 21, 2026

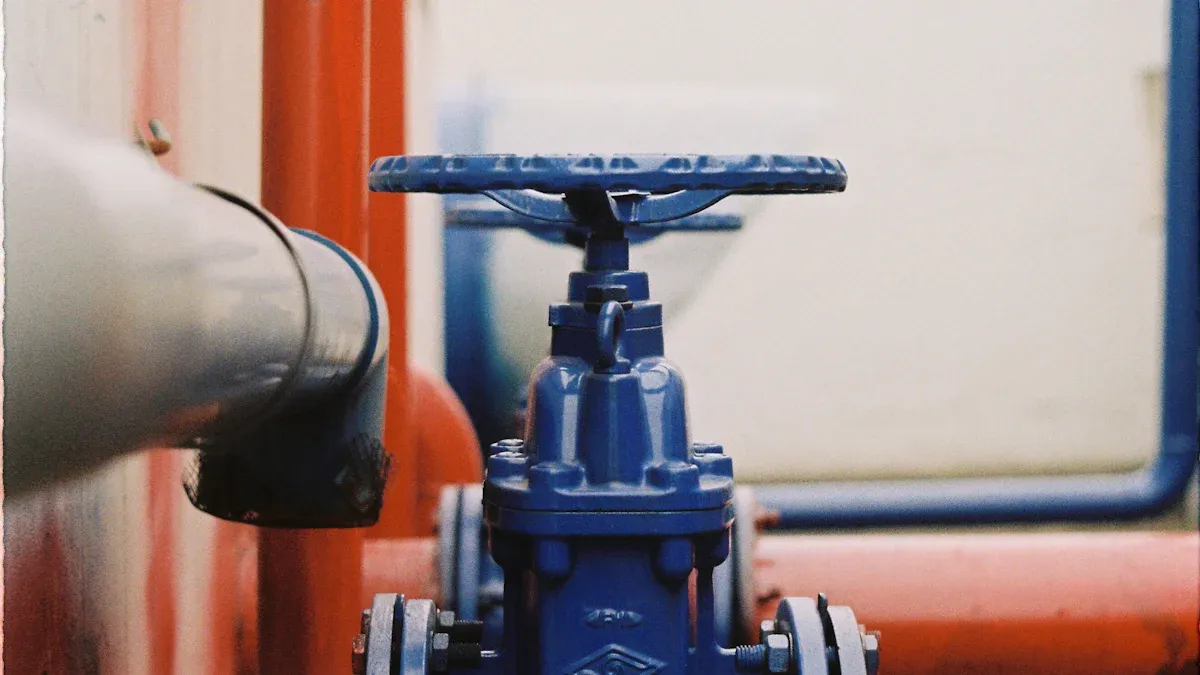

A gate valve is a type of shut-off valve designed for fully open or fully closed service. It operates by lifting a rectangular or circular gate out of the fluid's path. These valves are common in applications where minimal flow restriction is critical. Unlike a ball valve, this valve is not suitable for throttling flow.

A gate valve uses a multi-turn mechanism for operation. An operator must turn the handwheel multiple times to move the valve from open to closed. This action slowly raises or lowers the internal gate. The slow operation prevents water hammer, a risk associated with faster-acting valves. The design of the gate itself varies, which affects how the valve performs under different conditions.

Solid Wedge: This is the most common design. The gate is a single, solid piece of metal. It offers a strong structure but can sometimes get stuck if temperatures change significantly.

Flexible Wedge: This gate has a cut around its edge. The cut allows the gate to flex slightly, helping it seal tightly even with temperature changes or minor pipe stress. These valves work well in steam systems.

Slab Gate: This design uses a single gate that slides between two seats. When open, it creates a smooth, full-bore path for fluid, making it ideal for pipelines that require pigging.

A standard gate valve consists of the body, bonnet, stem, and gate. The valve body is the main structure that houses the internal parts. Manufacturers typically make the body from durable materials like cast or forged alloy steel. The bonnet covers the valve body and contains the stem. For high-pressure valves, a pressure seal bonnet design improves the seal as internal pressure increases.

The internal components that touch the fluid are called the 'trim'. The stem is a critical trim part. Engineers select robust materials for the trim to resist wear and corrosion.

Common Trim Materials

Trim materials for these valves often include high-performance alloys like Stellite, Hastelloy, and Monel. This ensures the valve has a long service life in harsh conditions.

These components work together to make the gate valve a reliable isolation valve for many industrial systems.

Engineers select a gate valve for its unique operational strengths, especially in large-scale industrial systems. These valves provide distinct benefits that make them the superior choice for specific isolation tasks. The design of this valve offers reliability in applications where other valves might fall short.

The primary advantage of a gate valve is its ability to provide an unobstructed path for fluid flow. When the valve is fully open, the gate retracts completely into the bonnet. This creates a straight-through passage that is the same diameter as the pipe. The result is very low friction and minimal pressure drop. This characteristic is crucial in systems where maintaining flow rate and pressure is essential.

When fully open, a gate valve can achieve a slightly higher flow coefficient (Cv) than even full-port ball valves. Its completely unobstructed flow path creates less resistance to fluid flow, making this valve highly efficient.

This minimal impact on flow makes these valves ideal for main water lines and other large-bore piping systems.

A gate valve excels in applications requiring simple on/off control. These valves are designed to be either fully open or fully closed. They are not suitable for throttling or regulating flow. Their robust construction ensures a tight seal when closed, making them reliable for long-term isolation. Many industries use these valves to isolate sections of a pipeline for maintenance or during emergencies. The slow operation of the valve prevents sudden pressure changes in the system. This makes the valve a safe and dependable choice for isolation service.

The symmetrical design of a gate valve offers a significant installation advantage. This valve can be installed in a pipeline without concern for the direction of flow. Both sides of the valve are identical, allowing it to seal and operate effectively regardless of how it is oriented. This feature simplifies the installation process and reduces the risk of incorrect placement, which can be a problem with some other types of valves. This bi-directional capability makes these valves a versatile and user-friendly option for system designers and installers.

A significant advantage of a gate valve is its robust performance in high-pressure and high-temperature environments. The design and materials of these valves make them exceptionally durable for demanding industrial services. Engineers often specify this type of valve for applications involving steam, oil, and gas where operational conditions are harsh. The inherent strength of the valve allows it to manage significant stress without failure.

The construction of these valves directly contributes to their resilience. Manufacturers typically use strong materials like carbon steel or stainless steel for the valve body. This material choice allows the valve to withstand extreme forces. For example, a standard Class 150 gate valve can handle pressures up to 285 psi, while a Class 300 valve can manage up to 740 psi at ambient temperatures. It is important to understand that pressure and temperature ratings are related; as the temperature of the service increases, the maximum allowable pressure for the valve decreases. This durability makes the gate valve a reliable choice for high-pressure systems.

The internal design of these valves also enhances their suitability for high temperatures. A gate valve often uses metal-to-metal seals, which do not degrade or fail at elevated temperatures like the soft seats found in many other valves. The simple, heavy-duty mechanism of the rising gate is less prone to thermal binding compared to more complex valve designs.

Design for Demanding Service

For the most extreme conditions, engineers use gate valves with a pressure seal bonnet. This advanced design uses the internal system pressure to strengthen the seal between the body and bonnet. As pressure increases, the seal becomes tighter, making this valve an excellent option for power generation and other high-pressure steam applications. This makes these valves a superior choice for tough jobs.

An engineer must weigh the disadvantages of a gate valve against its benefits. While these valves are excellent for specific isolation tasks, their limitations make them unsuitable for other applications. Understanding these drawbacks is key to designing a reliable and efficient fluid control system. The wrong valve choice can lead to operational inefficiencies and premature system failure.

The multi-turn mechanism of a gate valve results in slow operation. An operator must turn the handwheel many times to move the valve from fully open to fully closed. This deliberate, slow action is a significant disadvantage in situations requiring rapid shut-off. Unlike a quarter-turn ball valve, this valve cannot stop flow instantly in an emergency. The slow speed makes these valves impractical for process lines that need frequent or quick cycling. This operational characteristic limits the use of these valves to applications where speed is not a critical factor.

A gate valve is highly susceptible to wear if used for throttling. These valves are designed for fully open or closed service only. When an operator partially opens the valve, the fluid flow becomes concentrated and its velocity increases significantly. This high-velocity flow erodes the surfaces of the gate and the seats. The relationship between the valve's stem travel and the flow rate is nonlinear, with the most rapid changes happening near the closed position. This uneven flow can also cause the gate to vibrate, which further accelerates wear on the sealing components. This damage compromises the valve's ability to provide a tight seal, leading to leaks over time.

A gate valve may not seal effectively in low-pressure applications. Many designs, particularly the solid wedge type, rely on line pressure to help force the gate against the seats and create a tight seal. When the system pressure is very low, there may not be enough force to ensure a bubble-tight closure. This can result in minor leaks, which are unacceptable in applications handling gases or hazardous fluids. For these low-pressure services, other types of valves, like a ball valve, often provide superior sealing performance. The design of these valves makes them less reliable for systems that operate close to atmospheric pressure.

Gate valves possess a significantly larger physical profile and greater weight compared to other valve types, especially ball valves. The design of these valves necessitates a taller and bulkier construction. The gate must fully retract into the bonnet to create an unobstructed flow path. This requirement means the valve body must be tall enough to house the entire gate when open. This contrasts sharply with the compact, internal rotation mechanism of ball valves.

The substantial size directly contributes to the heavier weight of these valves. Manufacturers use more material, such as cast iron or forged steel, to build these robust valves. This increased material usage makes the valve heavier and often more expensive. The added weight presents several challenges during installation and system design.

Installation Impact ⚙️

Heavier valves often require mechanical lifting equipment, like cranes, for placement. This can increase installation time and labor costs, particularly for large-diameter valves used in industrial pipelines.

The larger footprint also limits where engineers can install these valves. They are not suitable for compact areas or systems where space is a premium. A direct comparison highlights the difference.

Valve Type (6-inch) | Approximate Height | Approximate Weight |

|---|---|---|

Gate Valve | 28 inches | 150 lbs |

Ball Valve | 10 inches | 60 lbs |

This table shows a typical gate valve can be almost three times taller and heavier than a comparable ball valve. This size and weight disadvantage makes other valves a more practical choice for many modern applications where efficiency and a smaller footprint are critical design factors.

Previous post

None

Related Products

Botou Yaxing Fluid Equipment Co., Ltd. specializes in providing design, development, and manufacturing services for the water valve industry. We produce high-quality valve products.

+86 186 3170 8948

No.4 Road Botou Industrial Zone, Cangzhou City Hebei Province, China

Get Free Sample

Privacy Policy

Privacy Policy